For help or advice get in touch

0113 257 2275

info@dcwoodhead.comDIESEL FUEL INJECTION

1) DCW Facilities –

-

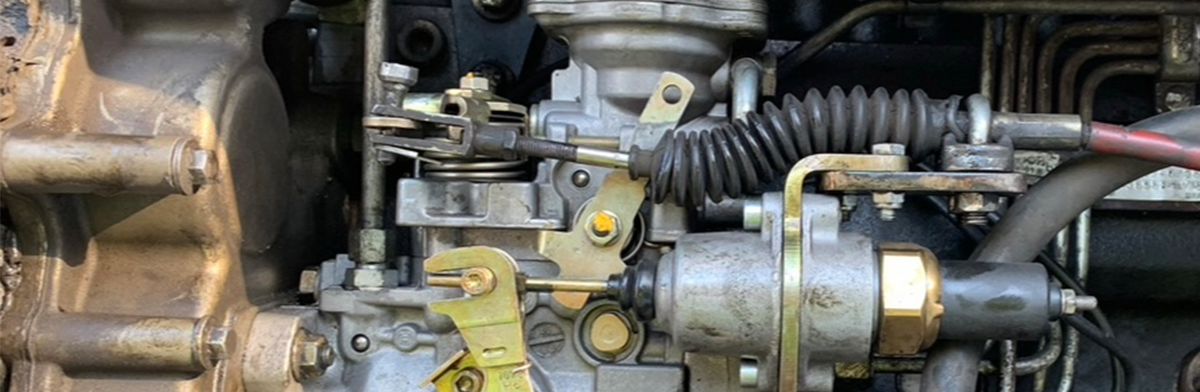

Our facilities at D.C. Woodhead and Partners, offers a variety of different beneficial aspect to ensuring our customers receive an efficient and effective service. We have a purpose-built facility and a specifically trained workshop, which is supported by a full working stores department and technical information office. Our premises also has vehicle access and forklift capabilities. Fuel pump and injector test benches and development rigs including benches up to 250kW and an injector test rig capable of testing MB430 injector. We offer a collection and delivery service, with our own fleet of collection vehicle, within a limited Leeds radius. We are also Robert Bosch and Stanadyne agents and have access to a wide range of technical and consumer data on demand at any time.

2) Large FIE Development -

-

DCW carries out large scale development work on behalf of UK based engine manufacturers to create Robert Bosch Fuel Injection Equipment systems (electronic or mechanical) to meet current and future performance, economy, emissions and legislative requirements. Infrastructure is in place to allow full endurance testing of large and small Fuel injection equipment systems, with the ability to specifically investigation into fuel injection equipment and perform comparison work between systems. The development work carried out, has played a vital role in progressing and improving large diesel systems all over the world. We pride ourselves on the ability to create and build specifically required test benches or rigs that can test a multitude of problems all at once, from the ground up, starting with an idea and making it a working and functioning reality.

3) Large FIE Repair –

-

We stock a large variety of parts (nozzles, elements, seal kits, etc.) held for repair and supply to engine manufacturers and other repairs (where parts are released).

As well as the large amount of parts we stock, we also have full cleaning and inspection facilities including ultrasonic cleaning tanks and fume cupboards.

Our workshop give us the ability to perform rebuild and testing on some of the largest fuel injection equipment there is, including specification updates and pressure testing, large common rail systems (CRI), eg. Cummins, GE, etc.

4) Small FIE Repair -

-

In accordance with ISO 9001 management system, we have the capabilities and technical data available to repair both in line and rotary fuel pumps from a variety of different manufactures. And exclusively repair Bosch Common Rail fuel injection equipment with state-of-the-art test equipment such as the Bosch EPS 205 and EPS 815 test benches. We upgrade and improve our workshop and test equipment where required to stay at the forefront of a very competitive and constantly evolving field. Following the strict principles of lean manufacturing, our workshop is one of the most efficient in the area. Staffed with apprentice trained technician, and training updated where required, we are at the front of an industry that is forever changing and growing.

5) Service -

-

Released units are updated, modified and rebuilt in accordance with manufacturer's requirements. Records are retained for all repairs, builds and reconditions, including test and calibration figures. All units are given a unique, traceable, job number.

Reports on the "as received" condition of the unit, if required. If the unit doesn't require recondition, we will return it to you with all relevant test data.

6) Spare Parts -

-

We are able to supply parts (from released units) for the following FIE types:

- Ambac

- Bosch

- CAV

- Delphi

- Denso

- Friedmann & Maier

- Mitsubishi

- Motorpal

- Sigma

- Stanadyne

- Zexel

And if we don’t have the part in stock, we can order it for you!